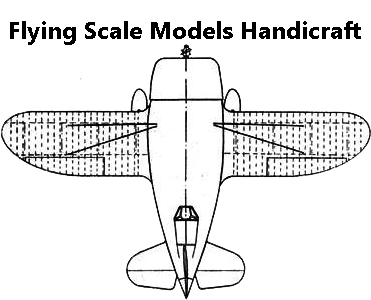

THE LEGEND GEE BEE R2 1:2.3 - handcrafted by WN & Team

THE LEGEND GEE BEE R2 1:2 - handcrafted by WN & Team - The NEW One!

THE LEGEND GEE BEE R2 1:2 - handcrafted by WN & Team

THE LEGEND GEE BEE R2 1:2 - handcrafted by WN & Team

THE LEGEND GEE BEE R2 1:2 - handcrafted by WN & Team

THE LEGEND GEE BEE R2 1:2 - handcrafted by WN & Team

THE LEGEND GEE BEE R2 1:2 - handcrafted by WN & Team

THE LEGEND GEE BEE R2 1:2 - handcrafted by WN & Team

Why timber wood construction

You can only reach the appropriate stability and rigidity as well as the light weight with a fuselage made of wood. Moreover a wooden fuselage is insensitive against heat and cold and you´ll never find hairline cracks after the influence of temperature, as you would find by using a fuselage made of synthetic materials.

During my active competition time I´ve seen a lot of model planes made of glass fiber reinforced plastics. Even the internet shows a number of incidents caused by material faults during aerobatics. The planes lost elevator unit and vertical tail or the fuselage has broken in the back part.

Unfortunately hairline cracks are not noticed before it is too late.

The advantage of a glass fiber reinforced plastics hull over a wooden fuselage is only the time of construction. A “plastic” hull could be made in a few hours, but the production of a wooden fuselage with scale-optics needs between 350 and 400 hours of handicraft.

There must be a reason why the Jodel Robin 400 is still made of wood and the price is four times higher than the price for a “standard” model plane out of glass fiber reinforced plastics.

All my models did have beard critical comparison with the models of my rival on the ground for many years. Rarely I didn`t win the construction judging with my sumless starts in national and international competitions.

During aerobatics my models persuaded – not only – the judges because of my construction, profiles of airfoils, weight and some additional features.

The most important feature of a model plane is a completely neutral behavior in the air, because otherwise a program with defined maneuvers is impossible to be presented perfectly. This is the requirement to win a competition, for sure. Although these very special models require a bit of flying experience to fly them successfully, I attach importance to absolute good nature in takeoff an especially landing.